One methodology that has gained significant popularity in recent years is Kaizen.

Kaizen originated in Japan, focuses on continuous improvement, and has proven highly effective in various industries.

This guide will provide a comprehensive overview of the Kaizen methodology within corporate learning, employee training courses, and continuous improvement, including its definition, origins, best practices, features, pros and cons, benefits, and examples.

Supercharge Your Training Courses – A Special Offer From Oak Innovation

Definition

Kaizen, derived from the Japanese words “kai” (change) and “zen” (good), can be translated as “continuous improvement.” Its philosophy and methodology emphasize making small, incremental changes to processes, systems, and behaviors to achieve ongoing improvement.

Kaizen involves the participation of all employees, from top management to frontline workers, and aims to create a culture of continuous learning and improvement within an organization.

Origins

After World War II, Kaizen was first introduced in Japan as part of the country’s efforts to rebuild its economy.

Toyota popularized it, becoming a fundamental principle of the Toyota Production System (TPS).

The success of TPS and the subsequent adoption of Kaizen by other Japanese companies led to its recognition as a robust methodology for achieving operational excellence.

Best Practices

To effectively implement Kaizen within corporate learning and continuous improvement, organizations should consider the following best practices:

- Engage all employees: Kaizen is most successful when all employees are actively involved in the improvement process. Encourage participation, gather input, and empower employees to contribute ideas and suggestions.

- Create a supportive culture: Foster a culture that values continuous improvement and encourages experimentation. Provide training and resources to help employees develop problem-solving skills and embrace a learning and growth mindset.

- Focus on small, incremental changes: Kaizen emphasizes minor, manageable improvements rather than large-scale transformations. Break down complex problems into smaller components and tackle them one at a time.

- Use data-driven decision-making: Base improvement efforts on data and facts rather than assumptions or opinions. Collect and analyze relevant data to identify areas for improvement and measure the impact of changes.

- Implement standardized processes: Establish procedures to ensure consistency and facilitate continuous improvement. Document best practices and share them across the organization.

Features

The key features of Kaizen within corporate learning and continuous improvement include:

- Continuous improvement: Kaizen promotes an ongoing cycle of improvement, where small changes are made regularly to enhance processes, systems, and behaviors.

- Employee involvement: Kaizen encourages the active participation of all employees, recognizing that they possess valuable insights and ideas for improvement.

- Problem-solving mindset: Kaizen fosters a problem-solving attitude, encouraging employees to identify and address issues proactively.

- Data-driven approach: Kaizen relies on data and analysis to drive decision-making and measure the impact of improvement efforts.

Pros and Cons

Pros of implementing Kaizen within corporate learning and continuous improvement include:

- Increased employee engagement: Kaizen empowers and encourages active involvement, leading to higher engagement and motivation.

- Continuous learning: Kaizen creates a culture of constant learning, where employees develop problem-solving skills and embrace a mindset of improvement.

- Incremental improvements: By focusing on small, incremental changes, Kaizen reduces the risk associated with large-scale transformations and allows quick adjustments.

Cons of implementing Kaizen include:

- Resistance to change: Some employees may resist the constant need for improvement or feel overwhelmed by Kaizen’s continuous nature.

- Time and resource-intensive: Implementing Kaizen requires time and resources to train employees, collect data, and analyze results.

Benefits and Examples

There are numerous benefits of implementing Kaizen within corporate learning and continuous improvement.

Some of the key benefits include:

- Improved efficiency and productivity: Kaizen helps identify and eliminate waste, leading to streamlined processes and increased productivity.

- Enhanced quality: Kaizen helps organizations deliver higher-quality products and services by continuously improving processes.

- Cost savings: Kaizen’s focus on waste reduction and efficiency improvements often leads to organizational cost savings.

- Employee satisfaction: Involving employees in improving and valuing their contributions can boost morale and job satisfaction.

Examples of Kaizen implementation within corporate learning and continuous improvement include:

- Daily huddles: Regular team meetings where employees discuss challenges, share ideas, and propose improvements.

- Gemba walks: Managers and leaders visit the workplace to observe processes, identify areas for improvement, and engage with employees.

- Kaizen events: Intensive improvement workshops where cross-functional teams collaborate to solve specific problems and implement changes.

Steps Involved

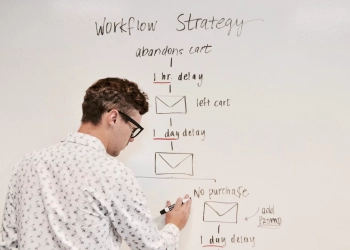

The steps involved in implementing Kaizen within corporate learning and continuous improvement typically include:

- Identify improvement opportunities: Analyze existing processes, systems, and behaviors to identify areas for improvement.

- Engage employees: Involve employees at all levels in improving and encouraging their input and ideas.

- Collect data: Gather relevant data to understand the current state, identify bottlenecks, and measure the impact of changes.

- Analyze data: Analyze the collected data to identify root causes, prioritize improvement opportunities, and develop action plans.

- Implement changes: Implement small, incremental changes based on the action plans developed in the previous step.

- Monitor and measure: Continuously monitor the impact of the changes and measure the results against predefined metrics.

- Standardize and sustain: Once improvements are implemented, establish standardized processes and practices to maintain achieved gains.

By following these steps, organizations can implement Kaizen and foster a culture of continuous learning and improvement within their corporate learning and continuous improvement initiatives.

Remember, Kaizen is a journey rather than a destination. It requires commitment, perseverance, and a willingness to embrace change.

With the right approach and dedication, organizations can reap the benefits of Kaizen and achieve sustainable improvements in their processes, systems, and overall performance.