Operational management is a critical function in any organization.

Operational management involves managing the day-to-day activities and processes that allow a business to function smoothly and meet its goals.

Having effective operational management practices in place is key to organizational success.

What is Operational Management?

Operational management refers to administrating and overseeing the processes, assets, and activities that produce and deliver goods and services.

It focuses on achieving efficiency, facilitation, quality, speed, and accuracy in business operations.

Operational management ensures resources are used appropriately and workflows run smoothly to optimize performance.

Features of Effective Operational Management

There are several key features of effective operational management:

- Strategic alignment – Operations are aligned with overall business objectives and strategy.

- Process optimization – Processes are designed, streamlined, and improved to maximize efficiency.

- Performance monitoring – Key performance indicators are tracked to identify issues and opportunities.

- Resource optimization – Resources like staff, inventory, systems, and equipment are optimized.

- Collaboration – Cross-functional collaboration ensures alignment between departments.

- Continuous improvement – Issues are addressed and processes refined continuously.

Benefits of Operational Management

Implementing robust operational management provides many benefits, including:

- Increased productivity and efficiency.

- Improved quality and customer satisfaction.

- Better utilization of resources.

- Reduced costs and wastage.

- Improved agility and responsiveness.

- Competitive advantage over rivals.

- More informed decision making.

Steps for Successful Operational Management

Managing operations successfully involves several key steps:

- Set operational strategy – Develop plans, objectives, and metrics aligned to business goals.

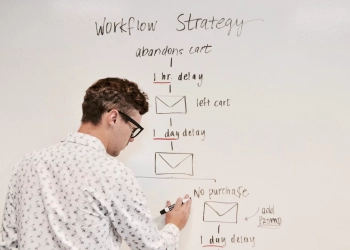

- Design efficient processes – Map out workflows and ownership, eliminate redundancies, and optimize productivity.

- Implement performance monitoring – Track KPIs to identify gaps, bottlenecks, and improvement areas.

- Leverage technology – Use solutions to automate processes and gain insights from data.

- Manage resources – Forecast demand, optimize inventory, maintain assets, and leverage human capital.

- Enable collaboration – Foster cross-functional teamwork and knowledge sharing.

- Drive continuous improvement – Proactively address issues, conduct audits, and refine processes.

- Report to management – Keep leadership and management informed with operational reports and recommendations.

15 Best Tools for Operational Management

There are many helpful tools available to improve operational management. Here are 15 top options:

- ERP software – Integrates processes and provides real-time data. Examples: SAP, Oracle, Microsoft Dynamics.

- MRP systems – Optimizes inventory and production scheduling. Examples: Fishbowl, JOBBOSS, Katana.

- WMS platforms – Manages warehouse operations. Examples: NetSuite, Manhattan WMS, HighJump.

- TMS solutions – Automates transportation logistics. Examples: MercuryGate, Blue Yonder, Transplace.

- HCM software – Streamlines HR processes. Examples: BambooHR, UKG Pro, Workday.

- PLM systems – Manages product lifecycle. Examples: PTC Windchill, Arena, Odoo.

- MES software – Provides manufacturing execution and control. Examples: Critical Manufacturing, Lighthouse MES, GE Digital.

- EAM platforms – Manages assets and maintenance. Examples: IBM Maximo, SAP PM, Fiix.

- BI tools – Enables data reporting and analytics. Examples: Tableau, Microsoft Power BI, Qlik.

- BPA software – Automates business processes. Examples: Kissflow, Nintex, Appian.

- RPA tools – Automates repetitive tasks. Examples: UiPath, Automation Anywhere, Blue Prism.

- PLCs – Controls manufacturing equipment. Examples: Allen-Bradley, Siemens, Mitsubishi.

- SCADA systems – Monitors industrial processes. Examples: Wonderware, GE iFIX, Ignition SCADA.

- CAD software – Automates design tasks. Examples: AutoCAD, SolidWorks, CATIA.

- Scheduling software – Optimizes scheduling and routing. Examples: Cohesive, ScheduleIt, TrackTik.

Operational Management in Action

Here are 5 examples of effective operational management in a corporate workplace:

- Supply chain optimization – A manufacturer uses data analytics to identify and eliminate supply chain inefficiencies. This improves supplier relationships and on-time delivery rates.

- Inventory management – A retailer implements an inventory management system across its stores. This provides real-time stock visibility, reduces waste, and improves product availability.

- Process automation – An insurance firm digitizes and automates key processes using RPA and workflow tools. This reduces processing times and allows staff to focus on value-added work.

- Quality assurance – A software company implements rigorous QA protocols including code reviews, testing, and customer feedback analysis. This improves product quality and reduces defects.

- Asset tracking – A hospital implements an RTLS system to track medical equipment in real-time. This increases asset utilization rates and staff productivity.

Conclusion

In summary, operational management and workforce management are vital for organizational success in today’s complex business landscape.

Following leading practices like process optimization, performance monitoring, collaboration, and leveraging the right technology can help boost operational efficiency, reduce costs, and enhance competitiveness.

Our corporate training material offers you ready-made training courses that are editable, user-friendly, practical, and flexible. We provide training guides, workbooks, PowerPoint slide-decks, activities, exercises, icebreakers, and more.

Special Offer – Course Packs Only $10.00 Each